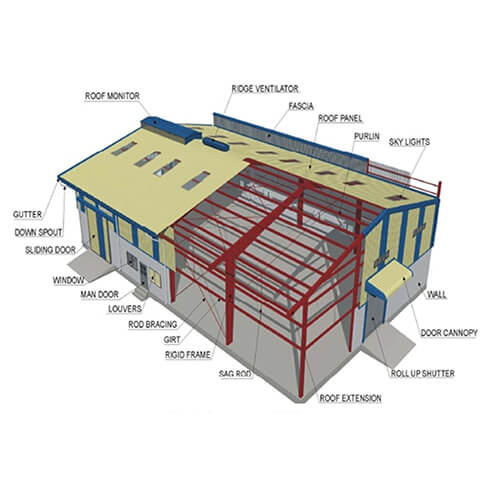

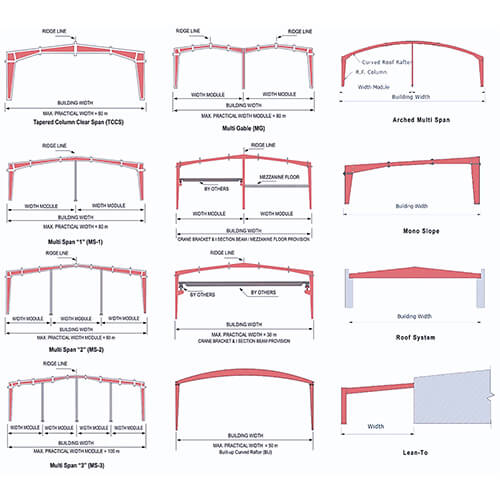

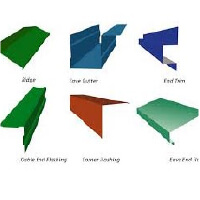

Meenakshi Industries is a Unit of SMCE GROUP, Serving the Industry Since 1995. Meenakshi Industries is Fast Growing Company in the Field of Design, Manufacturing & Erection of Pre Engineered Steel Building (PEB) and Heavy Structural Fabrication. Meenakshi Industries is a Team of More than 20 Qualified Professionals & Engineers having Rich Experience of Design, Production, Quality Assurance & Erection.

Meenakshi Industries is Dedicated to Provide the BESST Building Solutions.

Panipat is known as Asia’s Largest Handloom Hub, We Started as Engineering Consultants for the Textile Industry in the Field of Steam Energy Conservation, Designing of High Efficient Textile / Dyeing Machine & Various Pipe Line under the Dynamic Leadership of Our Founder Mr. Harish Shonak (Ex- Chief Manger Mech.) National Fertilizers Ltd (NFL).

In 2002 We started our Manufacturing Unit at Sector-25 Part-II HUDA, Panipat with the Vision to Provide the Energy Efficient Textile Machines, Energy Conservation Equipment and Pollution Control Devices. In Year 2008 After Completing his B. Tech in Electrical Engineering Mr. Mani Shonak Joined the Business and Extended the Reach from Textile to Rice, Milk, Rubber, Pharma, Paper, Food Processing. We Also Got the License from Govt. of Haryana under Indian Boiler Regulation (IBR) for Fabrication & Erection of Pressure Parts. In 2019 We Got Approval from India Oil Adani Gas ltd (IOAGL) for the Supply, Fabrication & Erection of Internal Gas Pipe Line in Industry.